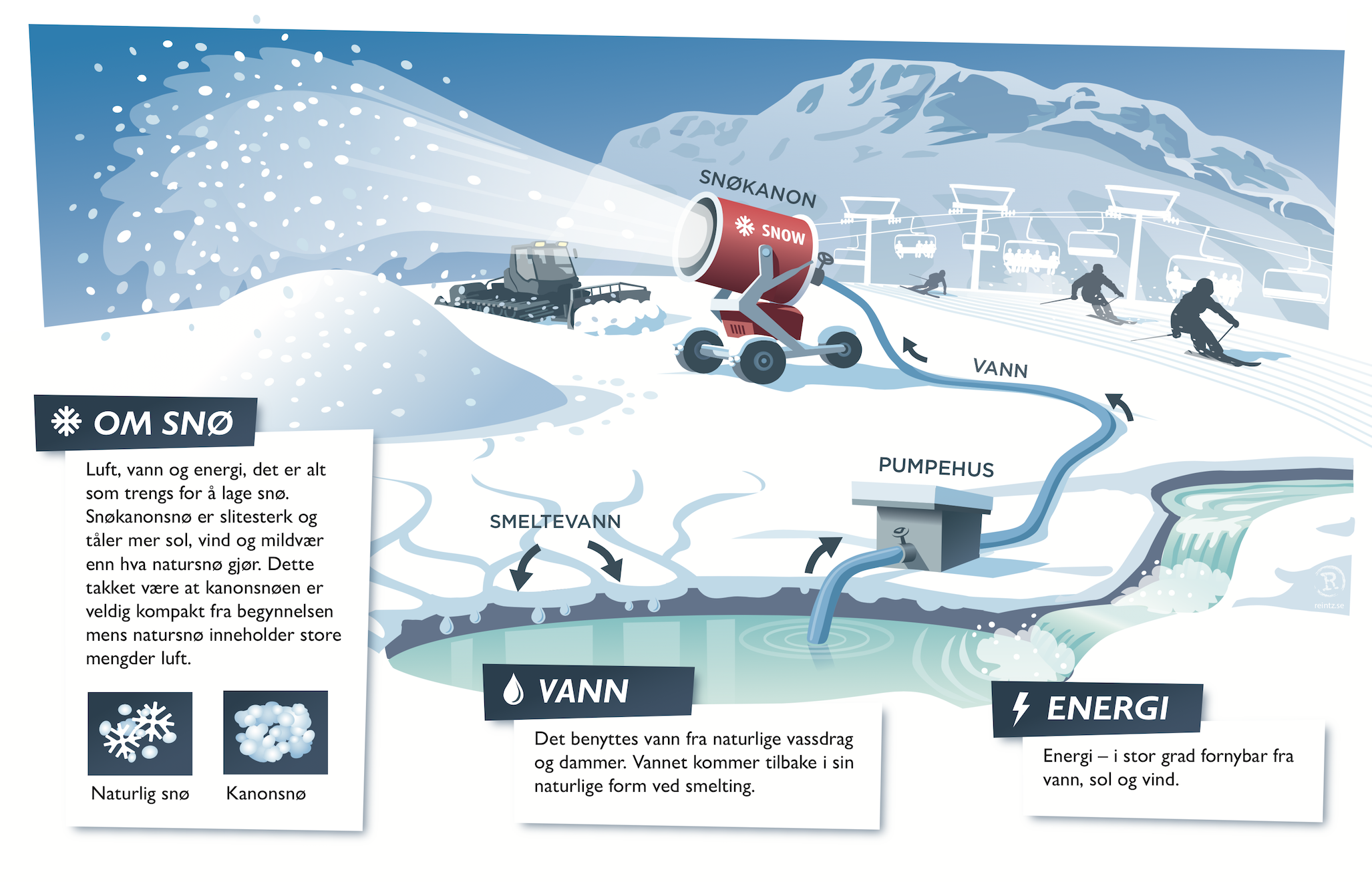

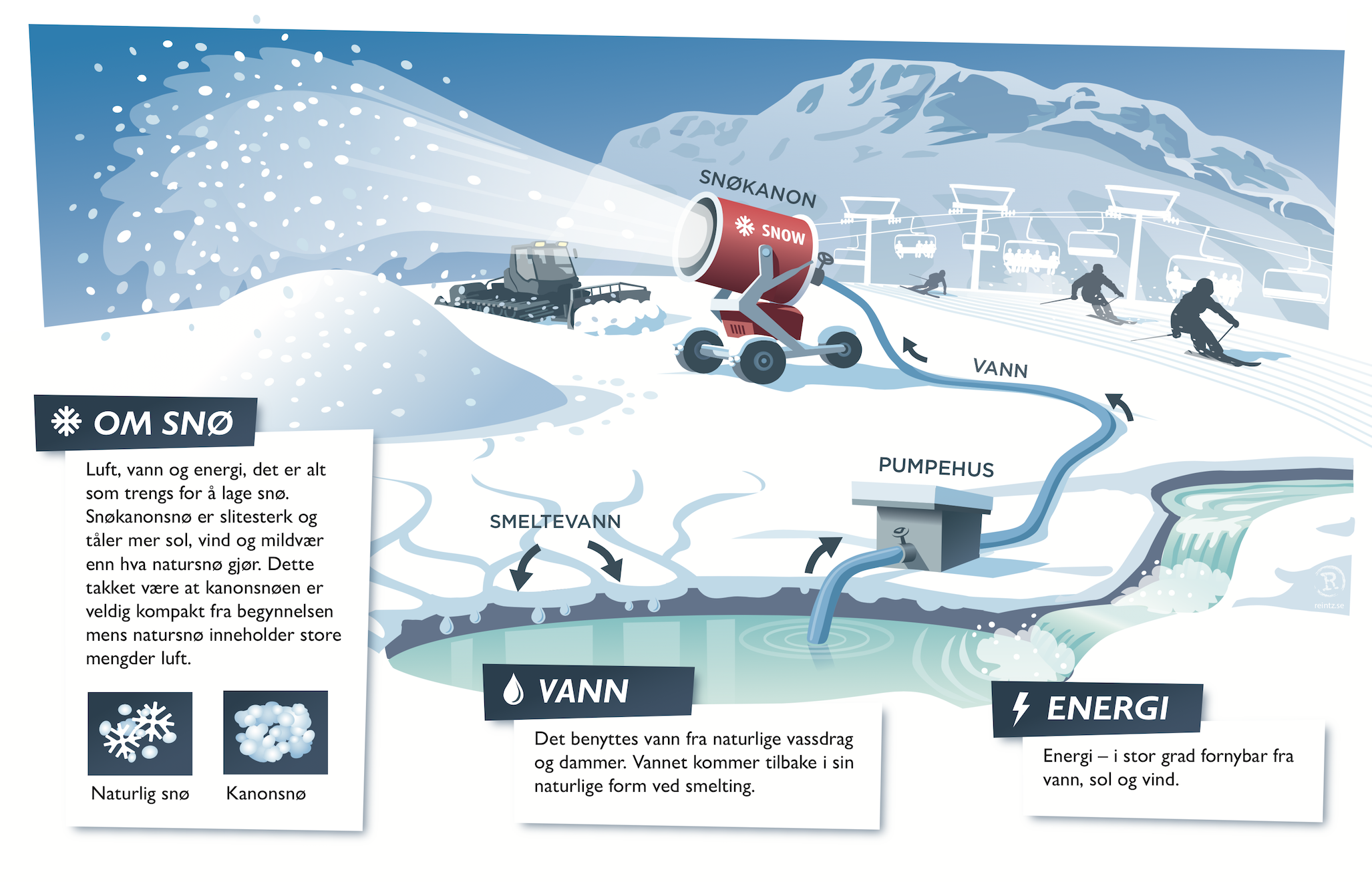

Optimale conditions

The optimal conditions for snow production are -10°C and clear weather, which typically brings dry air. The amount of snow produced depends on the temperature, so even though the snow guns are running full blast on the mountain, the number of cubic meters of snow will vary depending on how many effective degrees below freezing we have. The largest fan guns can produce up to 100 m³ per hour under ideal conditions. Under marginal temperature conditions, the same gun may only produce 5-10 m³ per hour.

In Andrebakken, some of the snow guns are permanently mounted on towers/arms along the side of the slope. These fan guns are connected to a central control system and can produce snow "automatically" when the temperature conditions allow. This makes snowmaking more efficient, and ensures a more consistent snow quality even as temperatures fluctuate throughout the day. In recent years, many large ski resorts have been upgraded with new automated systems, and significant investments have been made in both small and large resorts to ensure a good season despite variable weather conditions.

Water Capacity

The source for snow production is water from rivers, reservoirs, or natural lakes that have been regulated for this purpose. Since the water from rivers that come from the mountains cools quickly in the fall, these are ideal for snow production. Narvikfjellet draws water from the Narvik Waterworks – Forsnesvannet/Isvannet. We say that we borrow the water from nature, and it flows back when the snow melts.

Some wonder why not all the snow guns run at the same time when it's cold enough. The reason for this is that the water consumption per gun becomes so high that we don’t have enough water from the pump stations to operate more than, for example, 50% of the guns on the mountain.

Technology

The technological development of snow production systems has been significant in recent years. This development now gives us entirely new possibilities compared to before. Many ski resorts now have fully automated systems, where pump stations and snow guns are connected to a central control system. Snowmakers can monitor snow production at all times and adjust the number of guns in operation and production levels without having to physically be on the slopes all the time. Snow production can thus be more easily adapted to weather conditions and the resort’s production plan. The quality of the snow improves, and water and energy are utilized in an optimal way.

The snow gun itself has become an advanced production unit. Here, the water volume, nozzle regulation, snow placement direction, and other parameters set by the snowmakers are all controlled automatically in relation to the temperature and the system’s settings. New snow guns also use significantly less energy than older production equipment. Some types of guns have reduced energy consumption by up to 60-70%.

Snow production is based on renewable energy, meaning electricity. By utilizing new technology, energy consumption can be drastically reduced. Several ski resorts have now implemented advanced measurement equipment in grooming machines. The equipment continuously measures the depth of the snow under the machine during grooming. The grooming teams then have full control over the snow base and can manage the snow distribution to ensure a consistent snow base throughout the slope. When this system is connected to snow production, it results in a reduced need for artificial snow while still maintaining good snow conditions throughout the season. Measurements have shown that the amount of artificial snow can be reduced by about 30% when snow depth measurement is actively used.